ZIRCONIA CERAMIC COATINGS

Biologically Impervious™ refers to surface systems that are engineered with very specific characteristics to perpetually prevent the survival of microbes within and on infrastructure surfaces, which can destroy building materials as well as cross-contaminate food, water, animals, and humans.

All Zirconia systems include the following three characteristics and properties that make them Biologically Impervious™: non-porous, easily cleanable, active antimicrobial layers.

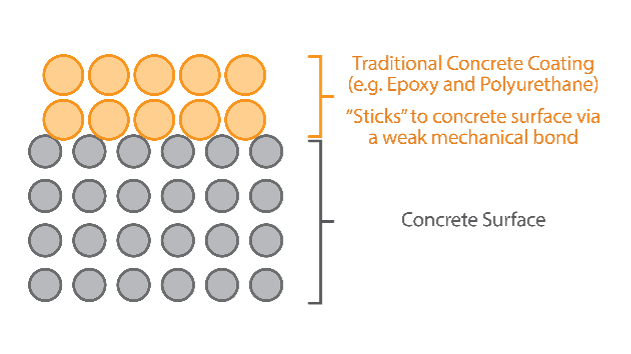

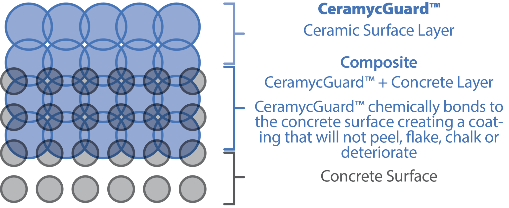

Non-porous: unlike any other surface coating, Zirconia’s ceramic surface technologies chemically bond with the surface and fills in all gross and microscopic pores. Pores are filled down to the single nanometer measurement, leaving nanopores so small that even the smallest microbe cannot penetrate, also blocking out moisture and nutrients needed for microbe survival. Compare this image of concrete treated with Zirconia’s CeramycShield with the porous raw concrete image above. (Insert image “Eliminates. Voids”)

Cleanable: due to the virtual elimination of all pores, and the combination of ceramic surface technology with urethane and other coating sealants (such as Zirconia’s ComposiCoat™ Floor Finish system), surfaces are so smooth that they are cleanable with just water. Because any cross-contamination of microbes would be limited to the surface only and without penetration into the surface material (through cracks, fissures, and pores as in non-treated surfaces), cleaning is less time and material intensive, and the use of harsh chemicals can be virtually eliminated (depending on the industrial use of the surface).

Active Antimicrobial Protection: All Zirconia coating systems employ some form of one or a combination of multiple antimicrobial mechanisms. The different types of antimicrobial actions can come through several different forms:

⦁ Bi-metallic surface using safe alumina-zirconia-silicate polymers that naturally oxidize and destabilizes microbe cell membranes (similar to the action of copper, silver, and platinum). This layer also prevents biofilm from forming on the surface.

⦁ The photocatalytic surface increases oxidation with UV light but will not break down with high UV exposure.

⦁ Antimicrobial additives mixed with the coatings in liquid form survive the drying process to provide continuous disinfectant action.

⦁ Nanosword surface technology that before Zirconia’s technologies provided only temporary antimicrobial action. Nanoswords include a carbon “sword” chain that projects from the surface to physically break apart microbe cell membranes. Zirconia’s surface coatings provide a more permanent bond with the nano sword technology for a long-lasting antimicrobial effect.

1. Preserving Old & New Infrastructure Indefinitely

Zirconia’s technologies create multiple paths to large scale greenhouse gases (GHG) reduction. Future technology development also looks promising.

Using Zirconia’s ceramic sealants to increase the durability of concrete and steel used to build major infrastructure represents a huge savings in greenhouse gases both near term and long term, because our advanced ceramic technology can repair, and restore existing infrastructure, and also dramatically increase the lifespan of new infrastructure.

What does this mean? Basically, Zirconia eliminates the “run-to-failure” construction/maintenance model that allows existing infrastructure elements to decay to the point of collapse, then requires re-digging of raw materials, reprocessing them, and remaking concrete and steel elements.

Concrete and steel are two of the largest sources of greenhouse gas emissions globally, roughly 18%. Any infrastructure asset (e.g., bridge, dam, etc.) built with concrete and steel is “GHG expensive”. So, saving these assets from decay and eliminating the need to remake them, saves enormous volumes of toxic greenhouse gas emissions.

What is the key takeaway? Most corrosion (chemical erosion) occurs at the surface of concrete and steel and works inward as the asset decays. If the surface of infrastructure assets is coated with Zirconia technology, the surface chemistry of concrete or steel is stabilized and preserved (no corrosion), and the entire asset is then preserved indefinitely.

2. Reducing Toxicity to the Environment

3. The Power of Substitution:

4. Reducing Toxicity to the Employees and Workers

5. Looking at the future...

Some Practical Challenges

- ⦁ Penetrating Chemical Adhesion

⦁ UV Immune

⦁ Pathogen resistance

⦁ Will Not Chalk, Peel, or Disbond

⦁ Biologically Impervious®

⦁ Clean/Dirty Entry’s

⦁ Showers

⦁ Office

⦁ Slats – Precast

⦁ Walkways (floor & walls)

⦁ Animal Load Chute (floor & walls)

⦁ D&D, Receiving

⦁ Laundry

⦁ Cistern Tanks

⦁ Kitchen/Break Rooms

⦁ Sidewalks

⦁ Truck Wash Bays

⦁ Feed Mills

⦁ Loading Docks

⦁ Wastewater Treatment

⦁ Greenhouses (floor & walls)

⦁ Commercial & Industrial Floors

⦁ Food Storage & Processing

⦁ Meat Processing

⦁ Dairy Parlor

⦁ Animal Husbandry

⦁ Live Animal Production

ComposiCoat™ Floor Finish

What is ComposiCoat?

Part 1: CeramycGuard™, the base layer, is an inorganic ceramic polymer that chemically crosslinks into the concrete surface, forming an ultra-durable ceramic composite. Part 2: CrossLinker™ VB is a hybrid compatibilizer-primer and vapor barrier which crosslinks the base ceramic composite to Part 3: ComposiCoat™ XD topcoat. The topcoat is chemical and abrasion resistant, easy to clean with biologically impervious properties. Once cured, all three layers are chemically bonded permanently into the ComposiCoat Floor Finish system. This composite flooring system has all the durability benefits of advanced ceramics and plastics technology, taking advantage of the best characteristics of both organic and inorganic coatings.

ComposiCoat™ Floor Finish

Product Description

With the ComposiCoat Floor Finish system, chemically unstable concrete is replaced by an ultra-stable ceramic-urethane composite, protecting it from chemical and physical erosion. This unique flooring system is also Biologically Impervious®, meaning it is designed to eliminate microbial habitat and continuously prevents microbial invasion and growth.

- ⦁ Easy to clean, non-yellowing, UV stable

⦁ Biologically impervious, preventing invasion and degradation by microbes

⦁ Superior abrasion resistance and durability

⦁ Chemically resistant to many types of acids, fuels, ammonia hydroxide, and many others (see ComposiCoat XD product data sheet for a full listing)

⦁ High solids, no odor, safe for indoor and outdoor use

⦁ VOC compliant Industrial Maintenance Coatings of North America

⦁ Tru-Composite® system that is resistant to subsurface concrete moisture

- ⦁ Farming, agriculture, dairy, livestock

⦁ Food production, manufacturing facilities, and storage rooms

⦁ Commercial flooring such as loading docks, distribution centers, parking ramps

⦁ Surgery/sterile rooms, waiting rooms, locker areas, exercise facilities, laboratories

Parking Garages (Walls)

Precast Products (Slabs, Pipes)

Cinderblock Walls

Bridges (Beams, Piers/abutments)

Seawalls & Wharfs

Dams

Storm Drains

Tanks

Tunnels

Wastewater Treatment

Water Treatment

Greenhouses (Walls and Floors)

Retaining and Sound Barrier Walls